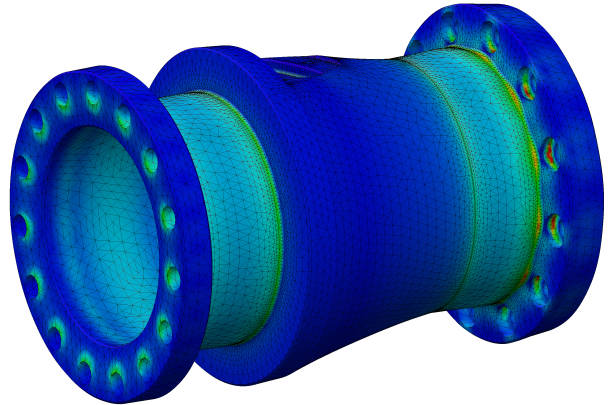

The Finite Element Analysis (FEA) method uses computers to predict how a structure or product will react to physical phenomena like vibrations, heat, and other real-world factors. This method simplifies complex geometries into smaller, more manageable components, allowing engineers to investigate and model materials and parts in a variety of contexts. This strong instrument is an absolute need in manufacturing, aviation, automotive, and civil engineering, among other fields, where precision and safety are paramount.

Finite Element Analysis (FEA) Benefits

- An improved product design

Before creating physical prototypes, FEA identifies potential weak points and error-prone areas to enhance product designs. This reduces the likelihood of errors and expensive redesigns.

- Effortless and affordable options

FEA can simulate the behavior of goods and structures digitally; it reduces the number of physical prototypes that are required. This not only speeds up the creation process, but it also drastically reduces the costs of materials and personnel, making it more affordable.

- Improved safety and compliance

The Federal Equipment Assessment Agency (FEA) verifies that products are up to code by investigating their behavior in extreme environments. This helps prevent potential safety hazards and ensures compliance with laws, making the product more dependable overall.

- Reduced time to market

Because FEA allows designers to rapidly test and improve their work, it shortens the product development period. Companies might gain a competitive advantage by bringing innovative products to market more quickly.

Engineering Solutions for Finite Element Analysis: Why Should You Use Them?

Having access to professional help

Experts in Finite Element Analysis have extensive knowledge and experience with FEA Simulation Services. Because they are field specialists, they can identify and resolve complex technical issues, ensuring accurate and dependable outcomes.

State-of-the-art instruments and gear

Expert FEA consultants can conduct comprehensive and precise simulations since they have access to cutting-edge software and hardware. In this way, we can eliminate any potential issues before we begin working.

Customised solutions

Businesses can acquire tailor-made solutions when they engage with expert FEA Simulation Services. If you are looking to improve an existing design or create a brand-new one, expert consultants can offer advice that leads to solutions that are both better-performing and less expensive.

Companies can reduce the risks associated with developing new goods with the assistance of finite element analysis consultants. Among these goals are preventing costly delays, ensuring rule compliance, and reducing the likelihood of errors.

Conclusion

Modern engineers rely on finite element analysis to speed up product development, save costs, increase safety, and enhance product design. Implementation of FEA Simulation Services offers a plethora of benefits to businesses and customizes services depending on the client requirements.

Businesses can rest assured on FEAmax, as they are known for offering top-notch FEA by providing great support and assistance. If you want detailed information about you can reach out to the engineering solution company by dialing a number at (240) 421-0756.