Over the past few years, 3D printing technology has become a significant transformative influence across a range of industries, heralding a new era of manufacturing characterized by increased efficiency, customization, and reduced waste. The oil and gas industry, a pivotal component of the global economy, is no exception. Houston, Texas, often referred to as the “Energy Capital of the World,” stands at the forefront of integrating 3D printing technologies into this critical sector. This integration is reshaping how oil and gas companies approach design, production, and operational challenges, promising significant improvements in both innovation and cost-effectiveness.

Importance of the Oil and Gas Industry in Houston, Texas

Houston is a crucial hub for the global oil and gas industry, serving as a central point for a dense concentration of energy firms and professionals. The city’s economic landscape is deeply intertwined with the energy sector, driving local and regional economic development and innovation, including advancements in 3D printing technologies in Houston, Texas. Home to major corporate headquarters, Houston also boasts extensive manufacturing, processing, and research and development facilities that continually push the boundaries of oil and gas production and management. Furthermore, the Port of Houston, one of the busiest ports in the United States, plays an essential role in the industry. It facilitates the efficient transport of oil and gas products globally, underpinning the strategic importance of Houston in the energy sector and its influence on global energy markets.

3D Printing in Oil and Gas Industry Market Forecast Report

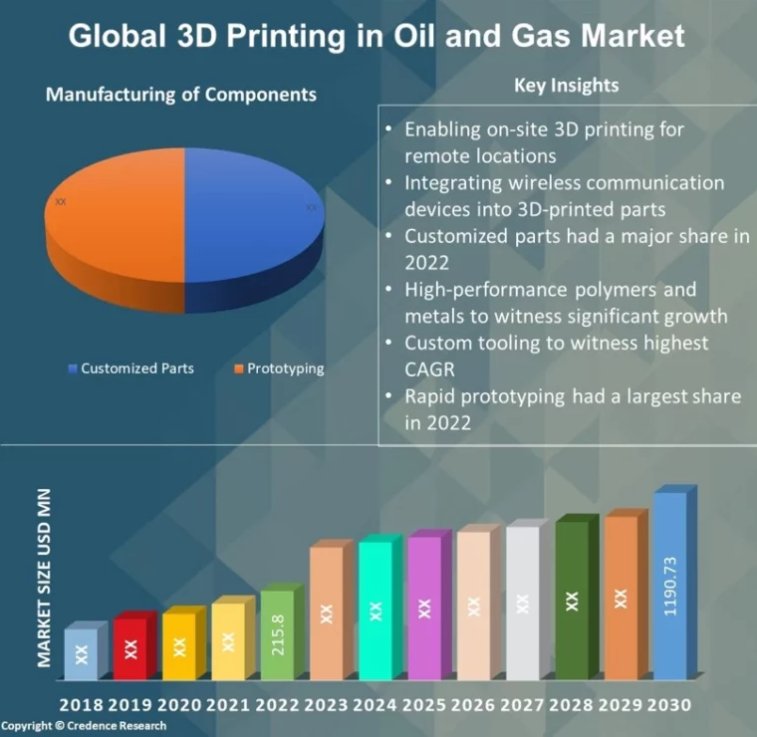

The global market for 3D printing in the oil and gas sector was valued at $215.8 million in 2022 and is projected to grow to $1190.73 million by 2030, with a CAGR of 23.80%. The market is driven by the need for customized parts, rapid prototyping, and on-demand manufacturing. The industry benefits from reduced manufacturing times, less inventory, and enhanced supply chain management. Asia Pacific leads the market, followed by Europe and North America, which is expected to grow the fastest. You can find more detailed insights at Credence Research.

Impact of 3D Printing on the Oil & Gas Industry

The oil and gas industry, known for its intensive engineering and technological requirements, has traditionally relied on conventional manufacturing methods to produce the necessary tools and components for exploration, drilling, and production. However, with the emergence of 3D printing in Texas, a transformative shift is taking place, offering more efficient, cost-effective, and flexible manufacturing solutions.

Overview of the Oil and Gas Industry’s Traditional Manufacturing Methods

Traditionally, the oil and gas industry has relied on conventional manufacturing methods such as casting, forging, and machining. These processes often involve high material costs, considerable waste, and inflexible production cycles. In contrast, Houston 3D printing services are beginning to provide viable alternatives that enhance flexibility and reduce environmental impact.

Key Areas Where 3D Printing is Being Utilized in the Oil and Gas Industry

- Prototyping

3D printing services in Houston are proving invaluable for rapid prototyping, allowing engineers to quickly produce and test prototypes. This accelerates the innovation cycle, enabling faster adaptation to new challenges and opportunities in the oil and gas sector.

- Tooling

The production of custom tools through Houston 3D printing services has revolutionized tooling processes. 3D printing offers a cost-effective method for producing bespoke tools that are both high-quality and tailored to specific operational needs.

- End-Use Parts Production

More than just prototypes, Houston 3D printing services are now used for the direct production of end-use parts. These components are crucial for ongoing operations, particularly in remote locations where traditional supply chains may fail to deliver efficiently.

Benefits of Using 3D Printing

- Reduced Waste

3D printing, a staple service offered by many Houston-based providers, significantly reduces waste compared to traditional subtractive methods, supporting more sustainable production practices in the oil and gas industry.

- Shortened Production Cycles

Providers of 3D printing services Houston ensure that parts are produced much faster than traditional methods allow. This rapid production capability is crucial for reducing downtime and speeding up the overall pace of operations.

- Customization of Parts

The flexibility of 3D printing allows for extensive customization, which is seamlessly handled by Houston 3D printing services. This adaptability is especially beneficial for creating components that meet the unique demands of specific projects or operational environments.

Innovations from Houston: Pioneering 3D Printing in the Oil & Gas Sector

Houston, known globally as an energy capital, is also becoming a hub for technological innovations, particularly in the realm of 3D printing. Several Houston-based companies are at the forefront of integrating 3D printing technologies into the oil and gas industry, driving significant improvements in operations and cost efficiencies. This section explores various case studies, collaborations, and the role of government and educational institutions in fostering this technological adoption.

Case Studies of Houston-Based Companies Adopting 3D Printing

Example 1: Custom Part Production for Offshore Rigs

One of the prominent 3D printing companies in Houston specializes in producing customized replacement parts for offshore drilling rigs. Traditionally, sourcing these parts could take weeks, but with 3D printing, the timeframe is reduced to just a few days. This rapid response capability not only cuts down operational downtime but also significantly reduces logistics costs, making it a game-changer for emergency repairs.

Example 2: Enhanced Tooling for Exploration Activities

Another case involves a Houston-based service provider that has developed specialized drilling tools through 3D printing techniques that are lighter and more durable than traditional models. These tools have proven to enhance the efficiency of exploration activities by improving the speed and accuracy of drilling operations, thereby reducing the overall project timelines and costs.

Specific Innovations and Their Impacts on Operations and Costs

The adoption of 3D printing by these companies has led to several specific innovations:

- Rapid Prototyping: Speeds up the design and testing phases, allowing for quicker iteration and innovation.

- On-demand Manufacturing: Reduces the necessity for maintaining large stock levels, as parts can be printed as needed on-site.

- Complex Geometries: Facilitates the production of parts with intricate geometries that traditional methods often can’t achieve, resulting in enhanced performance and efficiency.

These innovations have collectively led to a reduction in material waste, decreased production costs, and shortened lead times, all of which contribute to more streamlined and cost-effective operations.

Collaboration Between Tech Companies and Oil & Gas Giants

The synergy between 3D printing companies in Houston and major oil & gas corporations has catalyzed significant technological advancements. These collaborations often involve shared investments in research and development projects aimed at tailoring 3D printing technologies to meet the specific needs of oil and gas operations. For example, a collaboration between a leading 3D printing startup and a major oil company resulted in the development of a proprietary material for 3D printed parts that can withstand extreme pressures and temperatures encountered during oil extraction.

Government and Educational Institution Roles in Supporting Innovation

Local government and educational institutions in Houston play a crucial role in supporting these innovations. Initiatives such as grants and tax incentives are common, aimed at encouraging R&D and the commercialization of new technologies. For instance, the City of Houston has partnered with local universities to fund research into new 3D printing materials and methods that are particularly suited to oil and gas applications.

Moreover, educational institutions like the University of Houston offer programs and courses focused on additive manufacturing, producing graduates who are well-prepared to enter this evolving field. These graduates often find immediate employment with local 3D printing firms, helping to sustain the ecosystem of innovation.

Future Prospects of 3D Printing in the Oil & Gas Industry

The oil and gas sector, particularly in Houston, is on the brink of a transformative shift driven by 3D printing technologies. As these advancements continue to evolve, they promise to reshape how the industry operates, potentially bringing about significant economic and environmental benefits. This section delves into the expected technological advancements, integration predictions, and the potential impacts of adopting 3D printing in the oil and gas operations centered in Houston.

Upcoming Technological Advancements in 3D Printing

- Advanced Materials

One of the most anticipated advancements in 3D printing is the development of new, more robust materials that can withstand the extreme conditions typical in oil and gas environments. Research and development efforts by 3D printing services in Houston are focusing on creating materials that not only meet these rigorous standards but also offer improved performance characteristics, such as enhanced corrosion resistance and lighter weight.

- Improved Precision and Efficiency

Technological improvements in 3D printers themselves are expected to increase both precision and efficiency. These advancements include better resolution in printing techniques, faster production speeds, and more reliable end products. For Houston’s 3D printing services, these innovations mean being able to provide more sophisticated components at a quicker pace, further embedding 3D printing into the operational workflows of oil and gas companies.

Predictions for the Integration of 3D Printing in Future Oil and Gas Operations

- Customization at Scale

As 3D printing technologies mature, their integration into oil and gas operations is predicted to move beyond prototyping and small-batch production to full-scale manufacturing of customized components. This shift will allow for more personalized and optimized equipment designs that can be adjusted as per specific field requirements, enhancing overall operational efficiency.

- On-site Manufacturing

There is a growing trend towards developing portable 3D printing setups that can be used directly at oil and gas extraction sites. This shift would drastically reduce the time and cost associated with transporting parts from manufacturers to field locations, a particularly valuable advantage in remote or offshore operations.

Potential Economic and Environmental Impacts

- Cost Reduction

The economic impact of integrating 3D printing into oil and gas operations includes significant cost reductions in inventory management, logistics, and manufacturing. By enabling on-site production and reducing the need for large inventories of spare parts, companies can minimize capital locked in unused stocks and reduce waste.

- Enhanced Sustainability

Environmentally, 3D printing holds the promise of making oil and gas operations more sustainable. The additive nature of 3D printing minimizes waste production compared to subtractive manufacturing methods, contributing to conservation efforts. Furthermore, the ability to produce lighter and more efficient components can lead to reduced energy consumption during their use, lessening the overall environmental footprint of these operations.

The integration of 3D Printing Houston Texas into the city’s oil and gas industry represents a significant shift towards innovative manufacturing processes that promise to revolutionize this critical sector. As a hub of both energy production and technological advancement, Houston is at the forefront of adopting 3D printing technologies that enhance operational efficiencies, reduce costs, and pave the way for more sustainable practices. Through the ongoing development of advanced materials, improvements in printing precision, and the potential for on-site manufacturing, 3D printing is setting new standards for customization and rapid production within the industry. The collaboration between Houston’s 3D printing services and oil and gas giants, supported by educational institutions and government policies, continues to drive this transformation, ensuring that the future of oil and gas operations is not only more efficient but also more adaptable to the evolving global energy landscape.